The following are some of the ways to get in touch with each other:The owners of the newly-opened Print Studio hope to leave a mark on industry through a new approach in garment production and design, according to them.

Street WearhouseFrom its North Kansas City manufacturing facility, Alex Trinkle and Tyler Love specialize in embroidering and printing T-shirts, caps, and other clothing.

Matthew Gwin from Startland News took this photo of Alex Trinkle at Street Wearhouse.

Trinkle was the original creator of guerrilla streetwear. Clever Fools, said that Street Wearhouse takes a more artistic and “outside the box” approach to its screen printed designs in comparison to other print shops.

“The majority of print shop owners are not focused on the art aspect of printing,” Trinkle said. “There are more artsy print shops for sure. But, in terms of bringing in the quality and attention to details, and making a print more vibrant, I feel like our younger eyes can give a new perspective to our customers.”

Love said that as business owners younger than 30, Love and his partner place a high value on maintaining an excellent digital presence.

Matthew Gwin from Startland News took this photo of Alex Trinkle at Street Wearhouse.

“Even just having pictures on our website, that’s a separator from a lot of print shops,” Love said. “[Trinkle] handles all our social media, and a lot of print shops don’t do that. They don’t market themselves. … [Trinkle] has a personality that transfers through the screen, and that energy goes to the customers.”

Love added that Street Wearhouse also prioritizes the quality of its products over their quantity and focuses on a quicker turn-around time as opposed to lower pricing.

“We’re not going to be racing to the bottom competing on price,” Love said. “We’re going to be competing with quality and beating out other shops’ turnaround times. … We aim for five to seven business days without sacrificing quality.”

“A lot of shops try to win on pricing,” Love added. “We’re not trying to compete there, but we might win customers over because they can trust us; because they see the faces printing.”

Street Wearhouse: Matthew Gwin’s photo of Tyler Love and Alex Trinkle

Relationship ships

Trinkle and Love’s relationship predates Street Wearhouse; the two were high school classmates — though not close friends — growing up in Overland Park.

He recalled that they reconnected after Love had placed an order with Clever Fools, but it never arrived. This led him to contact Trinkle.

It turned out that their shipping mishap was a happy accident, since each had a special skill to offer. Trinkle had screen-printing skills, and Love had embroidery, direct-to garment (DTG), and machine.

“[Love] was doing DTG, and I needed somebody to make samples for me because when I would do pre-order drops, I wouldn’t have everything printed,” Trinkle recalled. “I saw an opportunity in him.”

Tyler Love of Street Wearhouse, photo by Matthew Gwin. Startland News

Tyler Love Street Wearhouse; Photo by Matthew Gwin of Startland News

Love originally picked up embroidery — and eventually, direct-to-garment — in 2019 after leaving an accounting job at Burns & McDonnellHe was a sharer.

“It was draining mentally because it was the same stuff every single day, but I would have never found [embroidery] if I didn’t take that job,” Love said.

The company he started is called Loves Branding, graduating from his first sewing machine to a semi-commercial machine as his contracts picked up — all while learning embroidery techniques online.

“During that time, I would spend a lot of time watching YouTube videos, and I subscribed to the University of YouTube 100 percent,” Love said. “You can learn almost anything on there.”

Eventually, Love “dipped into” direct-to-garment, a vertical which he said Street Wearhouse doesn’t use all that much. This skill set helped him connect with Trinkle.

“I learned a lot,” Love said. “I met a lot of people, [Trinkle] being one of them who I’ve been able to build that partnership with.”

Matthew Gwin from Startland News took this photo of Alex Trinkle at Street Wearhouse.

Scaling up to new challenges

Trinkle, the owner of Street Wearhouse, says they have seen consistent growth since their January opening.

Street Wearhouse

“We are growing so rapidly,” he said. “The bigger we are, the bigger problems we’ll face, so we have to be mentally ready for that. We’re going to have to learn through that process, which I’m nervous about, but at the same time, super excited about.”

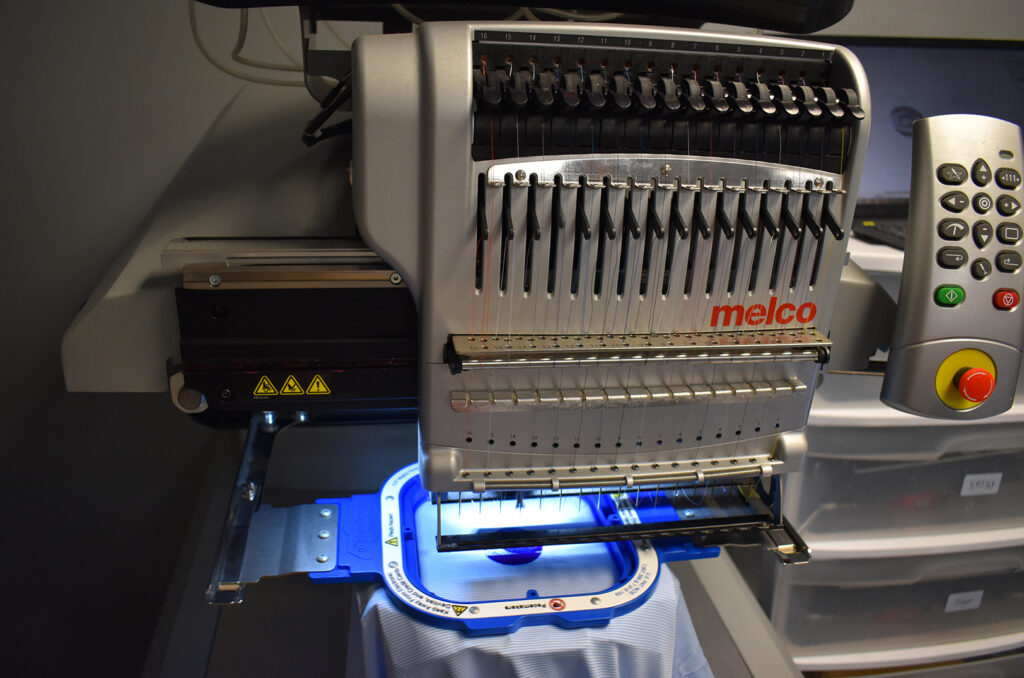

Love explained that adding a new automatic screen-printing system, upgrading to an embroidery machine with six heads, and streamlining back-end operations are the top three items to be completed to grow the business.

“If we can build these processes and workflows out where they work for us at this scale, then the processes themselves will scale with us,” Love said. “ We’re not overextending, but we’re allowing ourselves to take fairly decent strides in, hopefully, the correct direction.”

Love and Trinkle, who are scaling Street Wearhouse together, plan to hire more staff, confident that they can still count on each other for perspective and support.

“I think a business relationship is kind of like [the poem “Footprints”],” Trinkle said. “If one person falls, you have a friend to lift you back up, but if you do it by yourself, there’s nobody else to lift you back up.”

Street Wearhouse: Tyler Love, Alex Trinkle; Photos by Matthew Gwin of Startland News

Street Wearhouse offers Embroidery Machines

Street Wearhouse prints at Street Wearhouse

Love echoed those sentiments, highlighting how the two find common ground when their visions aren’t exactly aligned.

“Even when we bump heads and have disagreements, we always figure it out, and it ends up being the better answer,” he said. “If we never disagreed, that wouldn’t be a good business relationship at all.”

Love and Trinkle both agree, however, that Street Wearhouse’s future is still bright.

“It’s been a fun journey,” Love said, “and the road’s not going to end soon.”